Oil and gas

We are proud of our heritage and reputation for excellence in oil and gas fabrication and construction.

Our industry experience spans a wide variety of applications including subsea production systems, floating structures, overland pipelines and manifold pipework, and harsh operating environments including deep and ultra-deep water.

Through flexible contractual agreements we are able to provide dedicated support for the provision of specialist welding and coating services and solutions for our customers across the global energy and infrastructure sectors.

Onshore

CRC Evans provides specialist support for onshore projects through utilising our broad range of onshore pipeline construction equipment including automatic welding, bending machines, padding and crushing machines and weighting systems. Our fully integrated service delivery includes equipment, specialist personnel and technical support.

Offshore

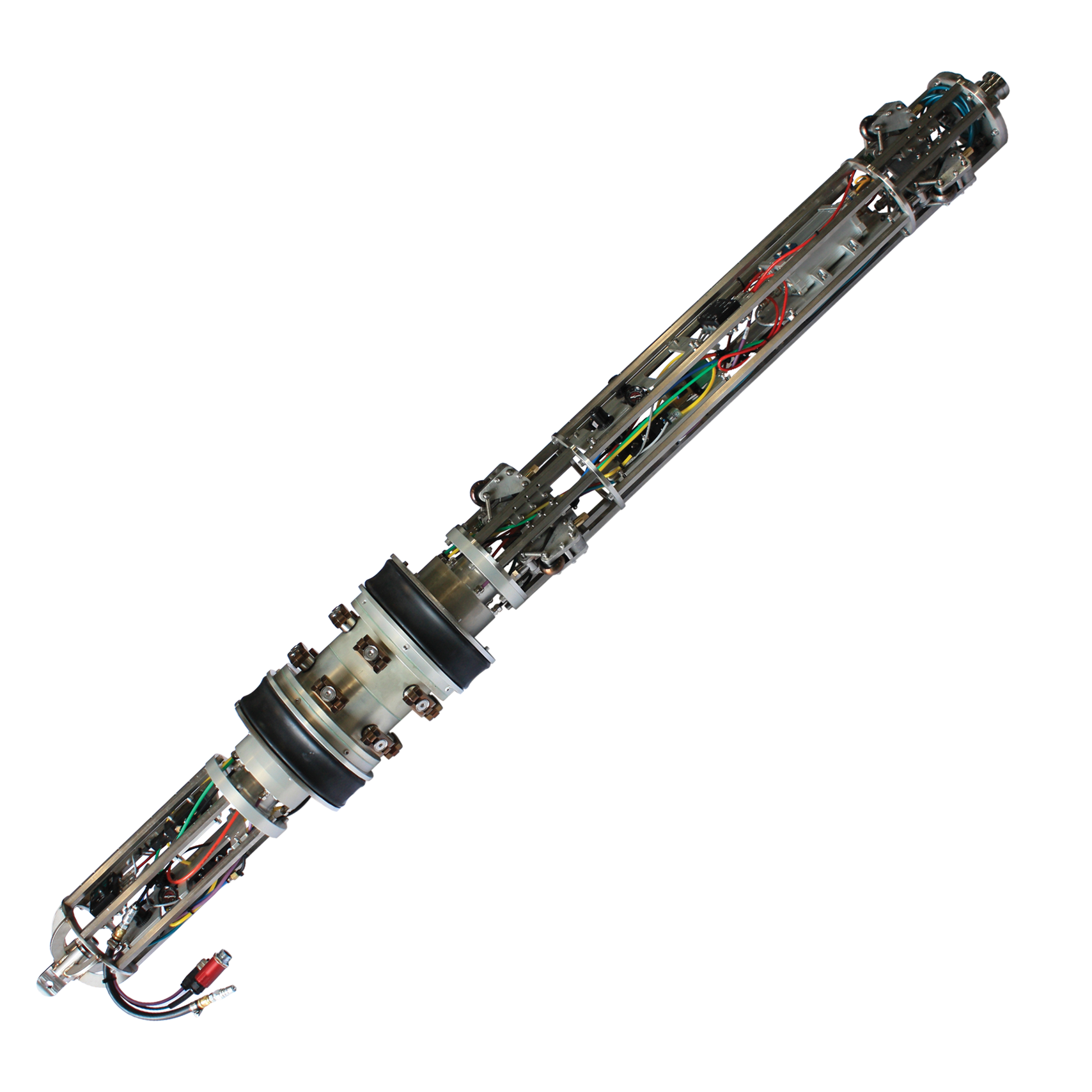

CRC Evans combine 90-years of offshore construction experience with unique pipeline technologies. Our offshore capabilities include comprehensive spoolbase, S-Lay, J-Lay, and fabrication services, with a focus on turnkey solutions. Our automatic welding machines and pipe facing equipment including copper backup clamps, purge clamps and support equipment, enables us to deliver comprehensive S-Lay solutions for shallow and intermediate waters. Our deep-water J-Lay pipeline construction welding solutions include J-Lay clamps and pipe facing machines, and external automatic welding systems capable of welding API 5L X70 or corrosion-resistant alloys (CRA), 13% chrome, stainless steel, or clad pipe.

Welding Systems

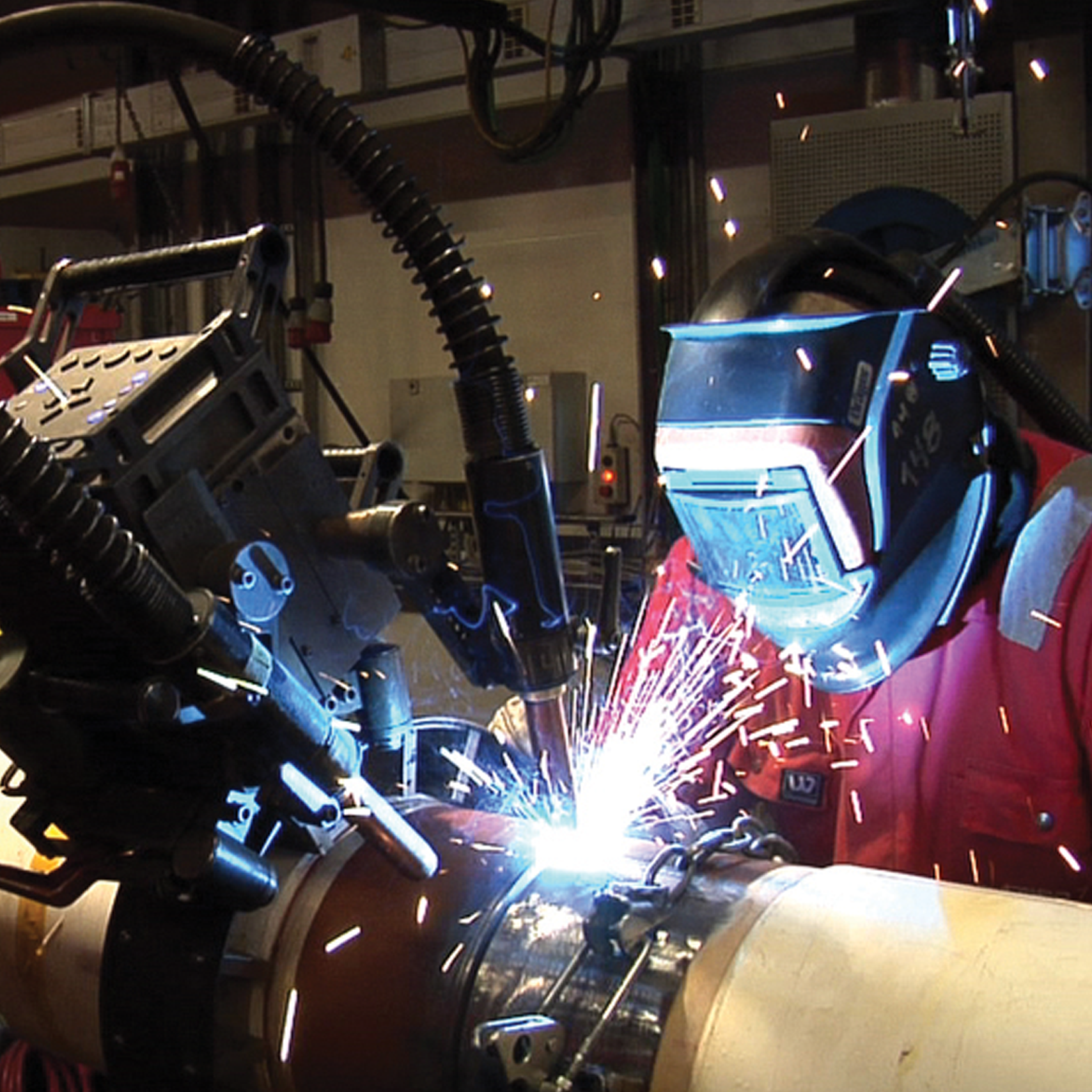

CRC Evans’ cutting edge automatic welding systems are lightweight and robust, built to work well in constrained spaces and with high reliability. Designed for high productivity, our advanced systems incorporate laser technology for thru-the-arc tracking with inline inspection capability that allow corrections to be made in the critical path, with fully digital control components.

Purge Control System

Fully automated pressure-based purge control system with laser vision. V-Purge controls and monitors purge chamber parameters and inline inspection.

Internal Inspection System

Internal inspection system with vision laser sensor and charge-coupled device (CCD) color camera. Allows root inspection directly after root and hot pass welding, minimising the downtime associated with third-party equipment.

We prioritise the health and safety of our people and aim to reduce incident risk through safe working practices and a quality-driven work environment

Contact our offshore team to find out how we can support your next project.